What is Green Chemistry?

In simple terms, Green Chemistry is maintaining environmentally sound practices through the lifecycle of a chemical product (design, manufacture, use and ultimate disposal) and processes. While this branch of chemistry is relatively new, there have been many reports done over recent years on environmentally safe practices in the laboratory.

The Goal of Green Chemistry

Understanding the chemical aspects of renewable energy

Using sustainable resources

Designing new, greener and safer chemicals and materials

Preventing pollution at the molecular level

Creating innovative solutions through safe chemical practices to solve real-world problems

Maintaining and designing new chemical products and processes to reduce intrinsic hazards.

Green Chemistry does not aim to aid in remediation (the clean-up of pollution). Instead, the goal is to create products that never contribute to pollution through specially designed chemicals. According to the EPA, “Most remediation activities do not involve green chemistry. Remediation removes hazardous materials from the environment; on the other hand, green chemistry keeps the hazardous materials out of the environment in the first place.

If a technology reduces or eliminates the hazardous chemicals used to clean up environmental contaminants, this technology would qualify as a green chemistry technology. One example is replacing a hazardous sorbent [chemical] used to capture mercury from the air for safe disposal with an effective, but nonhazardous sorbent. Using the nonhazardous sorbent means that the hazardous sorbent is never manufactured and so the remediation technology meets the definition of green chemistry.” 1

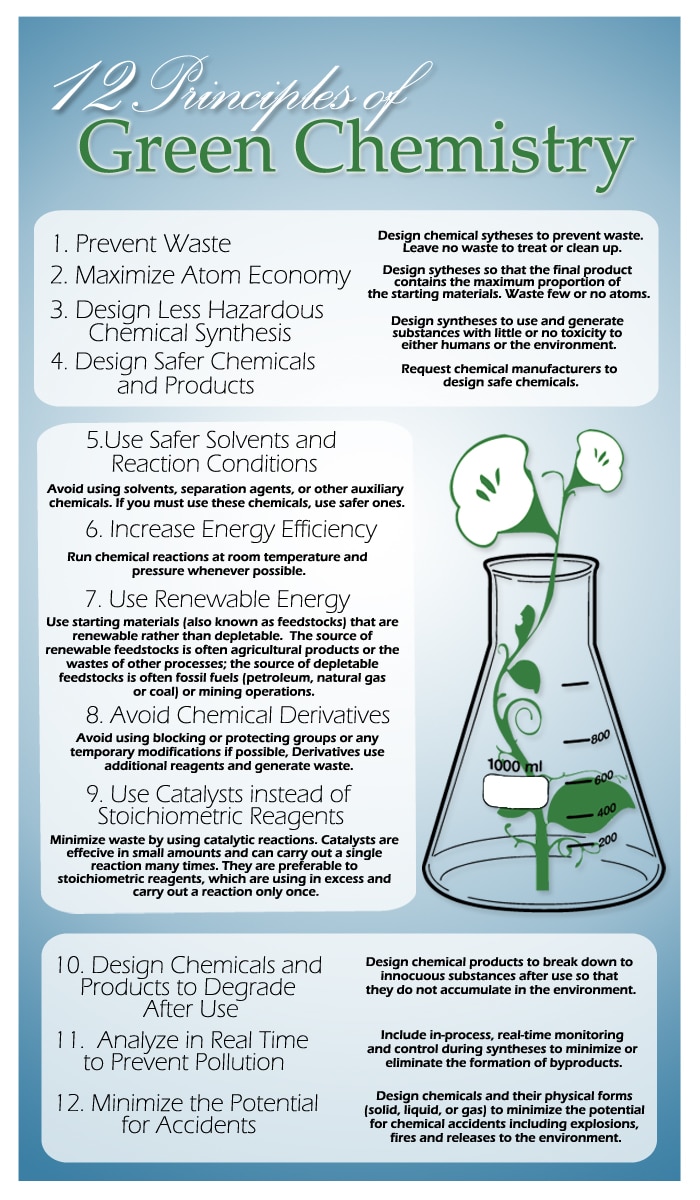

The 12 Principles of Green Chemistry according to the EPA:

1. Prevent waste: Design chemical syntheses to prevent waste. Leave no waste to treat or clean up.

2. Maximize atom economy: Design syntheses so that the final product contains the maximum proportion of the starting materials. Waste few or no atoms.

3. Design less hazardous chemical syntheses: Design syntheses to use and generate substance with little or no toxic either humans or the environment.

4. Design safer chemicals and products: Design chemical products that are fully effective yet have little or no toxicity.

5. Use safer solvents and reaction conditions: Avoid using solvents, separation agents or other auxiliary chemicals. If you must use these chemicals, use safer ones.

6. Increase energy efficiency: Run chemical reactions at room temperature and pressure whenever possible.

7. Use renewable feedstocks: Use starting materials (also known as feedstocks) that are renewable rather than depletable. The source of renewable feedstocks is often agricultural products of the wastes of other processes; the source of depletable is often fossil fuels (petroleum, natural gas, or coal) or mining operations.

8. Avoid chemical derivatives: Avoid using blocking or protecting groups or any temporary modifications if possible. Derivatives use additional reagents and generate waste.

9. Use catalysts, not stoichiometric reagents: Minimize waste by using catalytic reactions. Catalysts are effective in small amounts and can carry out a single reaction many times. They are preferable to stoichiometric reagents, which are used in excess and carry out a reaction only once.

10. Design chemicals and products to degrade after use: Design chemical products to break down to innocuous substances after use so that they do not accumulate in the environment.

11. Analyze in real time to prevent pollution: Include in-process, real-time monitoring and control during syntheses to minimize or eliminate the formation of byproducts.

12. Minimize the potential for accidents: Design chemicals and their physical forms (solid, liquid or gas) to minimize the potential for chemical accidents including explosions, fires and releases to the environment.

Pre:Cap Buying Guide

Next:NOT ANY MORE!